Thermography uses colours to represent thermal differences in an object. What value does the training bring to our company? We invite you to an interview with Marcin Krupa and Paweł Skierwczyński!

How was your stay in Silesia and the trip?

Paweł: We went to Silesia by train because of the comfort of the journey. First we went to Wrocław. From Wrocław we went to Świdnica. We saw what the Silesian railways are like, what the mentality of the people is like. A lot of people there use public transport. We had the opportunity to ride every type of transport: from the bus to the tram.

Marcin: We hit the mark with a hotel because we were 3 or 4 kilometers from the training place. We stayed in a hotel in the village. It was actually a building converted from a stable, a farm place. The owners had made a feast hall downstairs and there were rooms upstairs. There was quiet, peaceful and we even had air conditioning. It took us about 10 minutes by bus alone to get to the training place, to the palace in Krzyżowa.

Paweł: On the first day, we were taken to the Owl Mountains (pol. Góry Sowie). Very charming, beautiful views where we visited the Walim – Rzeczka and the Riese complex. During winter and autumn you can search for bats there with a thermal imaging camera. As a curiosity, these underground corridors, tunnels, so-called bunkers were built by prisoners of war themselves.

Speaking of the palace and training... How did you enjoy the training topics?

Marcin: The trainings were professionally conducted. We learned about the equipment, about the software, how to set up the cameras, what are the dependencies of the influence of the internal temperature and the sun (i.e. the so-called reflected reflection on the correct measurement). We did current calculations and familiarised ourselves with the standards. We learned why it is important to measure accurately. We were shown examples of bad connections. We spent almost the whole day setting up the cameras correctly. i recall when we went outside… it was over 36 degrees, the reflected temperature was negative… -3 or -4 degrees. We were very surprised by that.

Paweł: Measuring the objects in question involves pre-setting the camera to the parament of the environment in question. We need to know what material is being measured (everyone radiates heat differently). For this, we take into account the reflected apparent temperature, which reflects the radiation of any heat source falling on the target location and then being reflected towards the camera. The apparent temperature means that this is not the actual temperature of the object. From the point of view of the thermal imaging camera, it looks like the actual temperature, which is expressed in ° C.

What else is important? You have to set the right parameters according to the procedures that determine the parameter of the given conditions. i would add that in order to determine the reflected apparent temperature, you need a calibrated camera, a perfectly reflective material such as a piece of crushed and stretched aluminium foil. This should be done each time you move from room to room where the temperature is different. You attach this foil to the device you are going to measure, measure the temperature of this foil at the device with the reflected temperature entering the camera and maintaining the appropriate distance. You then take the measurement without the foil.

I got it... You have to pay attention to a lot of factors when are you using a thermal imaging camera. Returning to the topic of training, how did you spend the second day?

Marcin: We attended a lecture on electrical engineering. The lecturer made us a game. We played detectives with thermal imaging cameras. Hot and cold water was spilled on the floor in the lecture hall. We looked for traces of water, which were very visible on the camera. We could see in the camera how the temperature of the hot water was dropping.

Paweł: It was then colder than the ambient temperature. You couldn’t see this hot water, but what was evaporating from it.

Ineed, you had an interesting experience. You were at the electrical power and heating plant on the same day. How do you recall it?

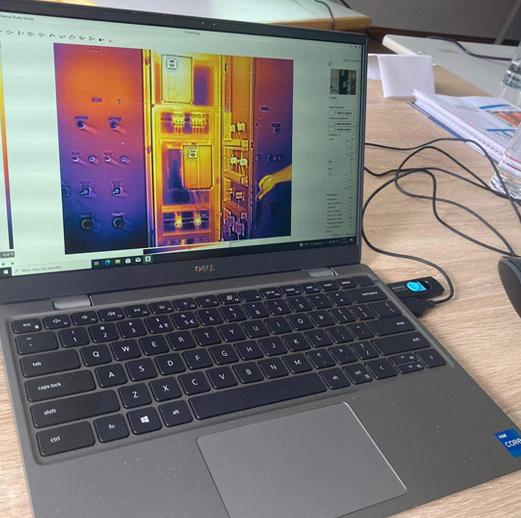

Marcin: The electrical power and heating plant was made typically for training. Inside there were transformers, cables, pump motors, among other things. We looked at the motor bearings, for example, to see if they were heating up. We took measurements with a thermal imaging camera on the transformers. And there was something about measuring with a thermal imaging camera where you could see a person on an insulator. And it turned out that it was my temperature that was reflected and you had to stand at an oblique angle so that the camera didn’t catch my body temperature. The conclusion was: you can’t stand and measure things straight.

Paweł: These are not simple measurements. You have to think carefully about what we even want to measure. Once you know what you want to measure, you have to set up the camera accordingly with the right material temperature. You also have to ask yourself what results you expect from the measurement.

What results can be expected?

Marcin: Let me give you an example: there are three cables, two are lit, one is not. Faced with this task, we need to know what we are supposed to measure. Then we can check: are these two cables heating up too much and the third one has a normal current flow or perhaps no current is flowing in it at all.

Thank you for the explanation. What added value did this training have for ADDIT?

Marcin: By having ISO 18434-1 and ISO 17024, we can do documentation for the insurance company. During the year, our broker requires for us to do thermal imaging measurements of all electrical connections, which we can now do ourselves and not use outsiders. We are able to produce the reports ourselves.

Paweł: We do the measurements to avoid fires. Additionally, it is prevention for us. We can inspect machines and check, for example, whether any bearings aren’t seizing up, whether all electrical connections in cabinets and connections are correct. This further protects us from machine downtime.

Marcin: With the new camera, we can now take pictures and immediately catalogue, describe and enter the number of the component being examined. The camera has a DSX system, which recognises the numbers on the cabinets, machines and cables itself. We gain enormous time optimisation by using the new camera. By describing and cataloguing the images already on the camera, at the “cycling” stage, it is easier and quicker for us to create a report and analyse it.

We can’t wait to go and take the first measurements and pictures, because this is how we learn and ground our knowledge

You have provided a lot of interesting content. i wish you good luck with your measurements and fault prevention!

Marcin and Paweł: Thank you very much!