Time of big production lots for sheet metal processing and contract manufacturing companies has gone. Today’s market expectation is short lead time and frequent deliveries as well as small lots in the shortest possible time. We can add to that short-term changes in projects and often no time for manufacturing sample products. All of these should be achieved without extra program costs, special tooling or high cost of machines set up.

It cannot perform this change thanks to faster machines. It requires rethinking of production management method, including the whole delivery chain. That is why Addit in order to meet our partner’s expectations or even exceed them in some areas is acting according to Industry 4.0 implements Smart Factory Project in relation to our production.

New approach

Current approach oriented to maximal utilization of resources fitting to big and midsize production lots will be replaced at Addit by managing of small and rapidly changing batches oriented to quick reaction and short time of a process.

Addit has extensive experience in High Mix, Low Volume, High Complexity production. However, what we have already achieved has met organizational challenges because of large diversification of production.

Setting up the machines is a significant cost, the more visible, if we are to produce one, two or a few pieces maximum. If we would have wanted to produce such small lots in a standard way, we would need to double our machine park, which obviously is related with increase of need for production area and employees. Assuming we could provide these resources, the product itself would be so uncompetitive that nobody would like to pay for it. That is why the best solutions is to create a mass production from such diverse low quantity products.

Change of philosophy

Special tooling has a similar importance in low quantities costs as setup time. Programming process must base on a digital 3D model. Special tooling for the bending process needs to be replaced by adjusting construction of a part to optimal production.

Year 2018 was for Addit a new opening. We had implemented a completely different philosophy of working. Part of our Smart Factory Project is a Smart Quick Small Lot Production program:

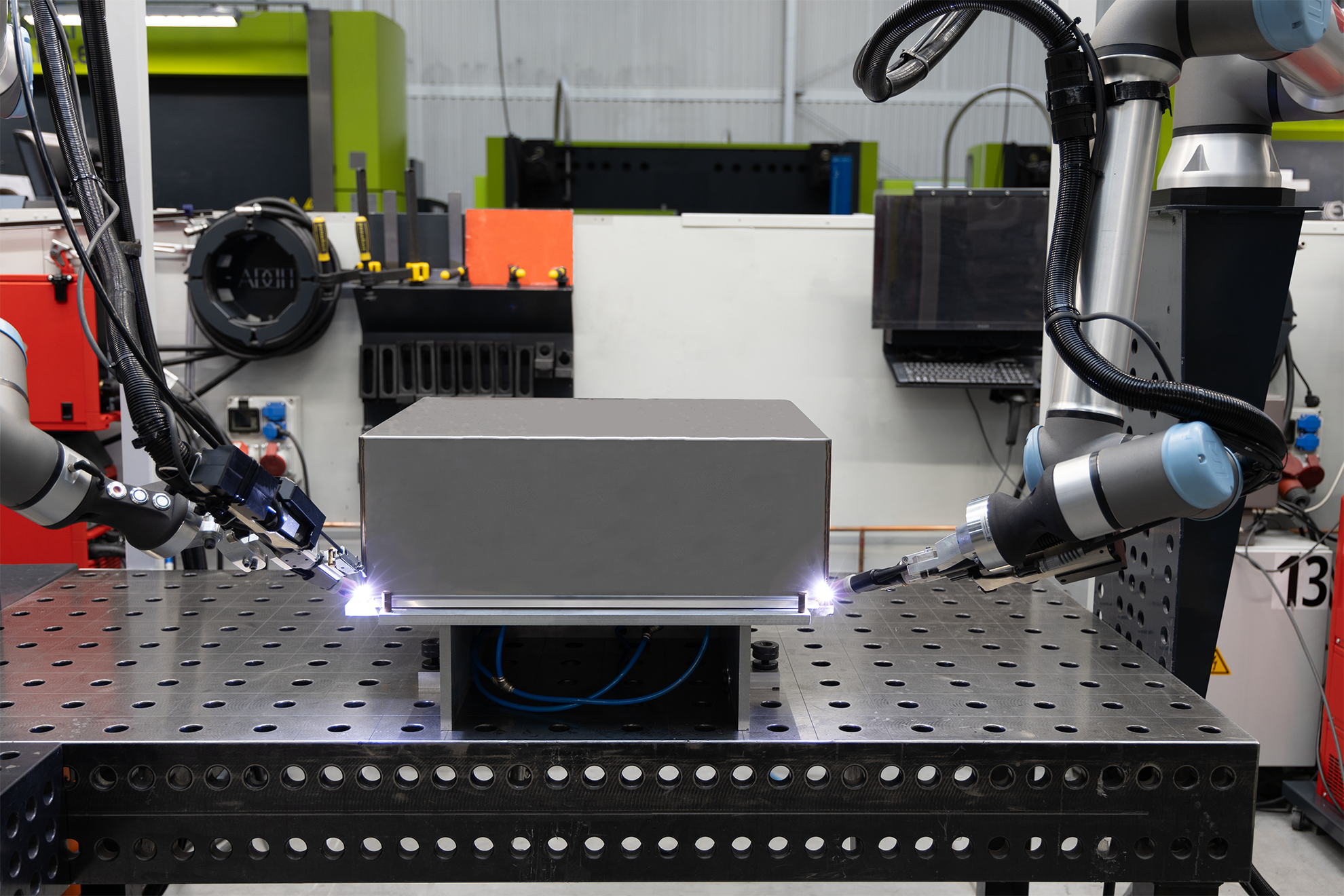

Smart – an automated system using digital 3D product models at every stage of the production process.

Quick – a system oriented to optimization of time of production’s order realization, eliminating not only downtime during production but also searching for improvements in delivery chain, using e.g. 3D printing as an alternative for purchasing of non-standard elements needed for project’s execution,

Small lot – a system assuring production of an exact quantity, which is required by customers, always at the same price regardless of the amount of the parts.

Logistics as the key to success

Another important element of the manufacturing cycle was a logistic service for products comprising over a dozen or even more parts. A special system trolley designed for this need is used to provide the highest standard.. All semi-finished products are transported on it for the next processing. This task is crucial in order to secure that all semi-finished products we arrive at the same time to each from the next production processes. Mentioned logistic solution gives us such a guarantee.

Production cells consisted of spot welding, welding, polishing and other accompanying processes will be organized so all employees could manufacture that products in a short period of time in the cell according to One Piece Flow rule.

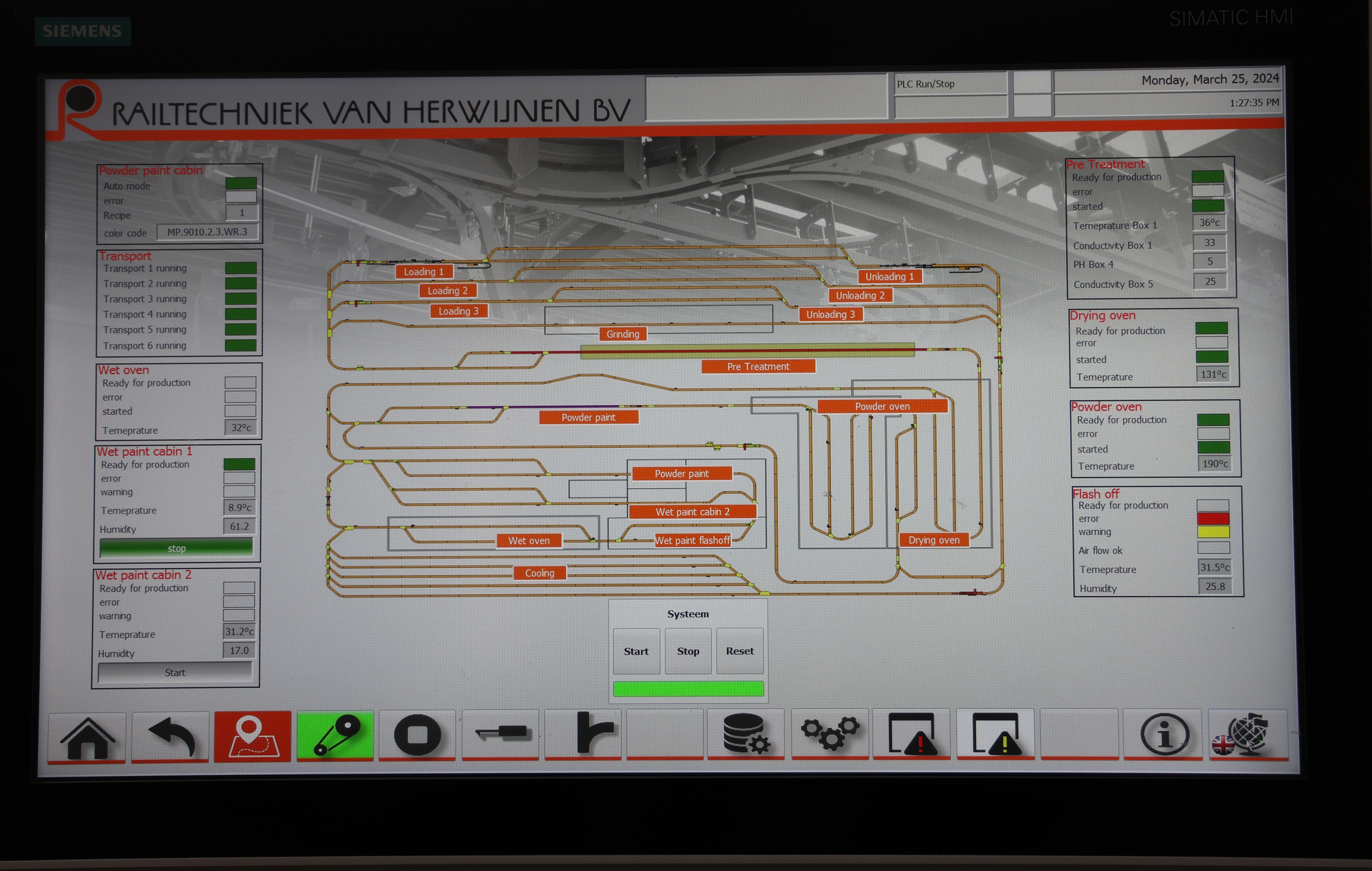

Next important step in the production management process is a collection on each machine and production stand. We can automatically register the cycle time of each and particular machine used for a given process. This gives a possibility of monitoring product’s realization status.

So complex, innovative and covering a wide spectrum, when it comes to production management Smart Factory project realized at Addit will enable our customers to increase their flexibility and competitiveness in the market. And we will continue to focus on constant improvement for needs of our business partners, employees and owners.